-

The busy traffic, prosperous industries and increasing power plants have yielded more and more hazardous gases and the other toxic matters, which have imposed feasible threats to earth and even influenced human survival. Environmental pollution is becoming the most urgent issue that we have to deal with. One of the most critical issues is the particulate matters (PMs) that are confirmed to influence the climate and individuals' health. It was reported that nearly 7 million premature deaths were induced by poor-quality air having PMs[1] as the dominant composition in 2012. With a growing number of death and disease, it is essential to reduce releasing PMs or the other polluting resources into air.

The PMs containing both small particles and liquid droplets are apt to be absorbed into lung and deleterious to creatures[2], which can be commonly avoided by wearing a proper mask to filter the harmful substances. As for the PMs generation from smoking cigarettes, a filter tip is usually used to reduce tar and parts of the droplets will be still inhaled into lung. Recently, an effective and flexible filtering nanofiber mat fabricated by electrospinning[2-4] was utilized as a window screen to keep good indoor air quality with a considerably high efficiency.

Electrospinning is a practical technology evolved from the electronic injection technology, which can be used to fabricate nanofibers[5], nanotubes[6] and nanobelts[7]. It has been widely applied to produce fibers with different morphologies[8-10] and properties [11-13] for various applications, such as to improve the performance of devices including the conducting wires[14], sensors[15], catalyst[16], carrier[17], etc. Due to the particularly porous nanostructure and material characteristics, it has been introduced to solve the pollution problems. Ref. [18] fabricated wool keratose/silk fibroin blend via electrospinning which acted as an efficient filter to remove the heavy metal ions in water. Moreover, Ref. [19] made it possible to electrospin the chitosan nanofiber then immersing in the K2CO3 solution and it performed good stability of resistance to erosion in water and a remarkable ability of absorbing Cu2+ and Pb2+ ions. In addition to heavy ions, electrospun nanofibers are also able to remove the organic pollution. Activated carbon nanofibers[20] prepared by stabilization, carbonization and activation after electrospinning polyacrylonitrile have been used to improve the capacity of the toluene adsorption. Recently, Ref. [3] fabricated polyimide nanofibers with excellent efficiency of PM removal even at a high temperature. The electrospun nanofibers showed a possibility in application of reducing toxic tail gases exhausted from vehicles.

In this study, we designed a filter device based on the eletrospun polyvinyl alcohol (PVA) fiber mats, which can be used as the air precipitator to filer liquid or solid matters from smoking steam. The morphology of nanofiber mats fabricated at various conditions was characterized by scanning electron microscopy (SEM) technique. The as-spun nanofiber mats were then fastened to the junction of glass tubes with a nested structure to evaluated the filtering efficiency. We also investigated the absorption efficiency of this device that was significantly affected by the diameter of nanofibers and the thickness of mats. The effect of gas flow rate (dependent on individual's vital capability or personal smoking habit) on removal efficiency was also taken into account.

-

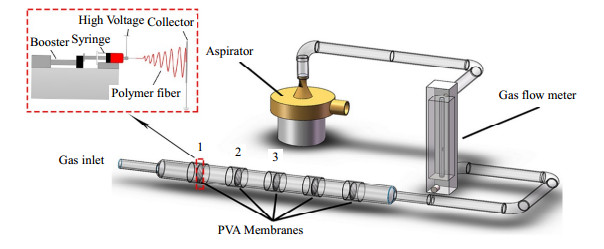

The polymer precursors used for electrospinning fibers were prepared by dissolving polyvinyl alcohol (PVA, Aladdin) with weight content from 8 to 10 wt% in deionized water and then rigorously stirred for 30 minutes at 85℃ to obtain transparent solutions. Subsequently, it stood at an ambient temperature for 12 hours to remove possible bubbles and get even dispersed solutions. Figure 1 presented the electrospinning setup used in this study, which consisted a high voltage power supply (1 mA, 0~30 KV, Dongwen High Voltage Ltd), a pump (Longer, LSP01-1A), a spinneret (21 gauge stainless steel needle tip) and a fiber collector (foil sheet). A high-power incandescent lamp was used to remain the humidity at around 40% and the temperature at 35℃. The distance between collector and spinneret was 15 cm. Applied voltage was ranged from 15 kV to 18 kV based on the concentrations of PVA, which had different viscosities of solutions. Copper grids with a diameter of 2 cm (the diameter of wire is 0.2 mm, the distance between wires is 1 mm) were adhered to the foil sheet to directly collect fibers in order to act as filters. The thicknesses of PVA films was adjusted by controlling the electrospinning time from 5 to 25 minutes. The morphology of nanofiber mats was characterized by scanning electron microscopy (SEM, FEI, Inspect F).

A nanofiber filter device was assembled to absorb matters from smoking stream as shown in Figure 1, which had three major parts including a filter channel, constructed by several glass tubes, that could fix the copper collector and nanofiber mats at each junction of tubes (we can adjust the junctions' diameter and quantity to enhance the efficiency of mass absorption). A gas flow meter was connected to control the flow rate of air and an aspirator supplied an air pressure to guarantee the air flowing in a certain rate. This device worked following the operational steps as firstly installing the mats and sealing the tubes, secondly switching on the aspirator to generate an air pressure and absorb the air into the filter channel and then adjusting the gas flow meter to keep the flow rate at a certain value, finally lighting the cigarette at the entrance of filter channel (the cigarette used in this study was PRIDE containing 11 mg tar, 1.1 mg nicotine and 11mg carbon monoxide).

The adsorbents on the filter were analyzed using X-ray photoelectron spectroscopy (XPS, thermo scientific, Escalab 250Xi).

-

The diameters of the as-spun nanofibers were first characterized by SEM, and the results are presented in Figure 2. Figure 2a, 2b and 2c illustrated the microstructure of electrospun nanofibers with different PVA concentrations of 8%, 9% and 10%, respectively. It can be seen that the diameters of nanofibers were enlarged from around 150 nm to 400 nm with the increasing the concentration of PVA, leading to a increase in the proportion of fiber area, which was mainly resulted from the variation of slurry viscosities. Furthermore, we utilized a Matlab code to quantitatively calculate the porosity of these nanofiber mats[21]. The derived porosities of the mats in Figure 2a, 2b and 2c are 37.3%, 38.16% and 18.39%, respectively. Figure 2d, 2e and 2f exhibited the typical SEM images of inhaled nanofibers (8% PVA, ET (electrospinning time) =10 min and ST (smoked time) =20 sec) with the different distance of the gas inlet from near to far. A remarkable decrease in the diameter of nanofibers occurred from nearly 150 nm to 100 nm. In addition, the porosities of smoked mats were calculated to 11.22%, 12.30% and 28.92%, respectively. Comparing to the mat in Figure 2a, the porosities of smoked mats had significant decreases, indicating that the nanofiber mats are able to purify air by absorbing the toxic substances from smoking stream.

Figure 3 depicted the microstructural evolution of the smoked mats with thickness and diameter. All the mats were smoked for 20 seconds and fabricated using 8% PVA and ET= 10, 15 and 20 min for Figure 3a, 3b and 3d. The ET remained 10 min for the mats in Figure 3c and 3e that contained 9% and 10% PVA. Note that there were five mats fixed in the channel in Figure 1 and all the mats shown in Figure 3 were the third mat in order to compare the filtering efficiency because the first and second one was saturated as presented in Figure 2.

Figure 3. The microstructure of the nanofiber mats as filters at the third series and porosity of nanofiber mats

The mat thickness was mainly controlled by the electrospinning time. The mats with ET= 10, 15 and 20 minutes corresponds to an enhancement in thickness. From Figure 3d and 3e, it was evident that the increase of mat thickness and fiber diameter to 400 nm could both enhance the absorption efficiency. Merely alien substances were observed in the mat with ET=20 min, but increasing the PVA content is effective to filter the smoking stream. It was observed that most of the tar in smoke had been absorbed by the first and the second mats in the 20 seconds' smoked process. The calculated porosities of mats in Figure 3a, 4b and 4d were 9.46%, 26.16% and 34.93%, respectively. With the diameter of nanofibers raising from ~150 nm to ~400 nm, the porosity was enhanced from 9.46% to 17.20% as shown in Figure 3f. Therefore, we could confirm that both the alteration of thickness and diameter of nanofiber had significant impacts on the filtrating efficiency in our work.

Figure 4. Effects of electrospinning time on the mass gain (The flow rate is 0.2 L/min for all test)

We note that the mat thickness in this study was directly related to the electrospinning time. Five PVA nanofiber mats were fabricated with 4 different ET from 5 min to 20 min as shown in Figure 4a, where the five same mats were installed in the channel and then they were inhaled by one whole cigarette. The flow rate of air was fixed to 0.2 L/min and measured by the air flow meter. Fibers with ET= 10, 15 and 20 minutes showed similar mass evolution tendency that mass gain decreased from the first to the fifth mat. The first three mats played very important role in removing the harmful substances. However, the second mat gained the maximum mass gain when the ET was reduced to 5 min due to the thinnest nanofiber mat that can't absorb too much substances if the flow rate was relatively high. In addition, the mass gain of fibers at the fourth and fifth mats was extremely low when the mats were relatively thick.

Due to the reduction in permeability for thick mats, an adjusted system was assembled to address the decreased efficiency occurring to the mats far from the cigarette. Figure 4b exhibited evolution of the filter mass with the mat thickness from the first (close to the cigarette) to the fifth mat, which was collected with ET of 5, 10, 15, 20 and 25 minutes, respectively. It showed quite a different tendency of mass evolution compared to the filter that was built using the same mats as displayed in Figure 4a, where the first mat was key to remove the tars in stream. Mass gain increased from the first to fourth mats, then a sudden drop at the fifth's, which could be contributed to the gradual saturation within the former fourth mats.

The increased thickness of the nanofiber mats enhanced the absorbing ability. Figure 4c demonstrated the total mass gain with different ET. The results indicated a high efficiency for the thicker nanofiber mats. The total mass gain raised from 7.5 mg to 12.5 mg with the ET increased from 5 to 20 minutes, indicating that an improved efficiency of 66.7% was achieved. Furthermore, it turned out that the system assembled with different thickness of nanofiber mats held the strongest capacity by adsorbing 14.8 mg, which was almost twice as much as that adsorbed by mat with a ET of 5 min. It was suggested that filtering system with multi-mats in thickness could realize higher efficiency if the mat had an incremental thickness.

The effect of air flow rate on the removal efficiency was also studied. Figure 5a and 5b presented mass gain of these nanofiber mats inhaled at different flow rates. The thickness of each mat was kept identical with a ET of 10 minutes. A similar tendency could be observed that mass gain decreased from the first mat to the fifth's at each flow rate. Comparing to the system at a high flow rate, mass gain of the mats far away from the cigarette at low rates showed considerably low values, which enabled the mats close to the cigarette had a relatively high filtering efficiency. Figure 5b exhibited variation of the total mass gain influenced by the flow rate. Absorbed mass increased significantly from 7.9 mg to 13.1 mg with increasing the flow rate, which could be attributed to that more smoking dust deposition on the side of tubes at low rate and also the mass of smoking dust will be enhanced if the rate of cigarette combustion is increased.

To further clarify the saturation of a nanofiber mat, a single mat inhaled by different smoking time was investigated. The ET for each filtering nanofiber mat controlled to 20 minutes and the flow rate of air was 0.2 L/min. Figure 5c showed the evolution of mass gain with the inhaling time. The mass grew with the time and finally saturated with a inhaling time around 200 seconds., in other words, a single nanofiber mat with a diameter of 2 cm and the ET=20 minute could absorb around 5 mg PMs from smoke stream.

X-ray photoelectron spectroscopy (XPS) was resorted to investigate the composition and the surface chemistry with deep elemental analysis of the inhaled nanofiber mat. Figure 6a showed the C1s signal for surface detected elemental composition with 5 major peaks. The peaks at 284.4, 284.8, 286.2, 286.8 and 289.0 eV corresponded to C-C[4], C-H[22], C=N[23], C=O[4] and COOH[22] bonds, respectively. As for the peak at 285.5 eV, it could be contributed to C-N and C-O[22] bonds. N1s signal consisting 3 major peaks was illustrated in Figure 6b. The peaks at 399.2, 399.8 and 400.7 eV could be indexed to C=N-C[24], C-N[4] and -NH-[24] bonds, respectively. In addition, 2 major peaks were represented in Figure 6c at around 532.3 and 533.0 eV, which corresponded to the C-O[25] and C=O[4] bonds. Other than C, O and N, a small fraction of S had also been detected. The overall XPS analysis suggested the surface of smoke-treated nanofiber mat was mainly composed of 4 major elements, namely, C, O, N and S, the ratio of which was 76.72%, 15.36%, 2.05% and 0.48%, respectively.

-

A smoke precipitator based on the polymer nanofiber mats was fabricated and used to filer liquid or solid matters from smoking stream. The nanofiber mats were first fabricated by an electrospinning route, then connected to the junction of glass tubes with a nested structure. The absorption efficiency of this device could be significantly enhanced by the increase of the diameter of nanofibers and the thickness of mats. The removal efficiency was also related to the gas flow rate. The results showed a stepped decrease of the mass gain at different order of mats, indicating the multiple filtering is significant and necessary for higher filtration efficiency. Possible elements and their composition in the cigarette smoking stream were finally analyzed.

-

Colleagues at Laser Fusion Research Center were acknowledged for kind helps in optical test.

-

摘要: 烟气中的焦油不仅对人体健康有害,并对环境造成一定的危害。该文采用静电纺丝技术制备了聚乙烯醇(PVA)纳米纤维,设计并实现了一种基于该纳米纤维薄膜的过滤装置,用于烟气中焦油的去除。滤膜吸收焦油后的质量增益是评价滤膜过滤效率的依据,该文研究了纤维直径、薄膜厚度和空气流速对滤油片的吸油量和焦油饱和度的影响,利用X射线光电子能谱分析了聚合物滤油片中可能存在的吸附物质。该工作展示了一种新型的过滤装置,可用于滤除、吸附香烟中的有害物质。

-

关键词:

- air precipitator /

- electrospinning /

- filtering /

- nanofiber /

- smoke

Abstract: Tar in smoking stream is detrimental to human health and has also exerted pressure on environment. In this work, the polyvinyl alcohol (PVA) nanofibers were fabricated using an electrospinning technique and a filter based on the nanofiber film was designed and implemented to eliminate tar from smoke stream. The filtering efficiency was evaluated by the mass gain of film after absorbing the tar. The fiber diameter, thickness of films and the inhaling rate affecting the quantity of tar absorption and the saturation of tar in filter were also investigated. The possible alien substances to the polymer filters were analyzed by X-ray photoelectron spectroscopy. The work demonstrates a novel filter device to abate hazardous matters in cigarette both for human health and a clean environment.-

Key words:

- air precipitator /

- electrospinning /

- filtering /

- nanofiber /

- smoke

-

-

[1] WESTERVELT D M, HOROWITZ L W, NAIK V, et al. Quantifying PM2.5-meteorology sensitivities in a global climate model[J]. Atmospheric Environment, 2016, 142:43-56. doi: 10.1016/j.atmosenv.2016.07.040 [2] LIU C, HSU P C, LEE H W, et al. Transparent air filter for high-efficiency PM2.5 capture[J]. Nature Communications, 2015, 6:6205. doi: 10.1038/ncomms7205 [3] ZHANG R, LIU C, HSU P-C, et al. Nanofiber air filters with high-temperature stability for efficient PM2.5 removal from the pollution sources[J]. Nano Letters, 2016, 16(6):3642-3649. doi: 10.1021/acs.nanolett.6b00771 [4] KHALID B, BAI X, WEI H, et al. Direct blow-spinning of nanofibers on window screen for highly efficient PM2.5 removal[J]. Nano Letters, 2017, 17(2):1140-1148. doi: 10.1021/acs.nanolett.6b04771 [5] ZHAO Z, SHEN X, YAO H. Alumina nanofibers obtained via electrospinning of pseudo-boehmite sol/PVP solution[J]. Journal of Sol-Gel Science and Technology, 2014, 70(1):72-80. doi: 10.1007/s10971-014-3276-x [6] LI D, XIA Y. Direct fabrication of composite and ceramic hollow nanofibers by electrospinning[J]. Nano Letters, 2004, 4(5):933-938. doi: 10.1021/nl049590f [7] PAN Z W, DAI Z R, WANG Z L. Nanobelts of semiconducting oxides[J]. Science, 2001, 291(5510):1947-1949. doi: 10.1126/science.1058120 [8] LI D, MCCANN J T, XIA Y, et al. Electrospinning:A simple and versatile technique for producing ceramic nanofibers and nanotubes[J]. Journal of the American Ceramic Society, 2006, 89(6):1861-1869. doi: 10.1111/j.1551-2916.2006.00989.x [9] LIM J M, MOON J H, YI G R, et al. Fabrication of one-dimensional colloidal assemblies from electrospun nanofibers[J]. Langmuir, 2006, 22(8):3445-3449. doi: 10.1021/la053057d [10] WEI L, QIN X. Nanofiber bundles and nanofiber yarn device and their mechanical properties:A review[J]. Textile Research Journal, 2016, 86(17):1885-1898. doi: 10.1177/0040517515617422 [11] HUANG Z M, ZHANG Y Z, KOTAKI M, et al. A review on polymer nanofibers by electrospinning and their applications in nanocomposites[J]. Composites Science and Technology, 2003, 63(15):2223-2253 doi: 10.1016/S0266-3538(03)00178-7 [12] JAWOREK A, KRUPA A, LACKOWSKI M, et al. Nanocomposite fabric formation by electrospinning and electrospraying technologies[J]. Journal of Electrostatics, 2009, 67(2-3):435-438. doi: 10.1016/j.elstat.2008.12.019 [13] LACKOWSKI M, KRUPA A, JAWOREK A. Nonwoven filtration mat production by electrospinning method[J]. Journal of Physics:Conference Series, 2011, 301(1):012013. [14] POL V G, KOREN E AND ZABAN A. Fabrication of continuous conducting gold wires by electrospinning[J]. Chemistry of Materials, 2008, 20(9):3055-3062. doi: 10.1021/cm7036958 [15] LIU H, KAMEOKA J, CZAPLEWSKI D A, et al. Polymeric nanowire chemical sensor[J]. Nano Letters, 2004, 4(4):671-675. doi: 10.1021/nl049826f [16] SU L, JIA W, SCHEMPF A, et al. Free-standing palladium/polyamide 6 nanofibers for electrooxidation of alcohols in alkaline medium[J]. Journal of Physics Chemistry C, 2009, 113(36):16174-16180. doi: 10.1021/jp905606s [17] XU X, CHEN X, XU X, et al. BCNU-loaded PEG-PLLA ultrafine fibers and their in vitro antitumor activity against Glioma C6 cells[J]. Journal of Controlled Release, 2006, 114(3):307-316. doi: 10.1016/j.jconrel.2006.05.031 [18] KI C, GANG E, UM I, et al. Nanofibrous membrane of wool keratose/silk fibroin blend for heavy metal ion adsorption[J]. Journal of Membrane Science, 2007, 302(1-2):20-26. doi: 10.1016/j.memsci.2007.06.003 [19] HAIDER S, PARK S Y. Preparation of the electrospun chitosan nanofibers and their applications to the adsorption of Cu(Ⅱ) and Pb(Ⅱ) ions from an aqueous solution[J]. Journal of Membrane Science, 2009, 328(1-2):90-96. doi: 10.1016/j.memsci.2008.11.046 [20] OH G Y, JU Y W, KIM M Y, et al. Adsorption of toluene on carbon nanofibers prepared by electrospinning[J]. Science of the Total Environment, 2008, 393(2-3):341-347. doi: 10.1016/j.scitotenv.2008.01.005 [21] YU G, LI T S, XU M, et al. Fabrication of nickel-YSZ cermet nanofibers via electrospinning[J]. Journal of Alloys and Compounds, 2017, 693:1214-1219. doi: 10.1016/j.jallcom.2016.10.001 [22] PAOLETTI L, DE BERARDIS B, ARRIZZA L, et al. Influence of tobacco smoke on indoor PM10 particulate matter characteristics[J]. Atmospheric Environment, 2006, 40(18):3269-3280. doi: 10.1016/j.atmosenv.2006.01.047 [23] SABBATINI L, MALITESTA C, GIGLIO E D, et al. Electrosynthesised thin polymer films:The role of XPS in the design of application oriented innovative materials[J]. Journal of Electron Spectroscopy and Related Phenomena, 1999, 100(1-3):35-53. doi: 10.1016/S0368-2048(99)00039-0 [24] DEMENTJEV A P, GRAAF A D, SANDEN M C M V D, et al. X-Ray photoelectron spectroscopy reference data for identification of the C3N4 phase in carbon-nitrogen films[J]. Diamond And Related Materials, 2000, 9(11):1904-1907. doi: 10.1016/S0925-9635(00)00345-9 [25] KENDALL M, HUTTON B M, TETLEY T D, et al. Investigation of fine atmospheric particle surfaces and lung lining fluid interactions using XPS[J]. Applied Surface Science, 2001, 178(1-4):27-36. doi: 10.1016/S0169-4332(01)00248-3 -

ISSN

ISSN

下载:

下载: