| [1] |

WISE M, CALVIN K, THOMSON A, et al. Implications of limiting CO2 concentrations for land use and energy[J]. Science, 2009, 324(5931): 1183-1186. |

| [2] |

ZHENG L T, WEN L, SUN C, et al. Ternary thermoelectric AB2C2 Zintls[J]. Journal of Alloys and Compounds, 2020, 821: 153497. |

| [3] |

QIU P F, SHI X, CHEN L D. Cu-based thermoelectric materials[J]. Energy Storage Materials, 2016, 3: 85-97. |

| [4] |

SHIOTA Y, OHISHI Y, MATSUDA M, et al. Improvement of thermoelectric property in Ce filled Fe3Co1Sb12 by Sn addition[J]. Journal of Alloys and Compounds, 2020, DOI: 10.1016/j.jallcom.2020.154478. |

| [5] |

BERETTA D, NEOPHYTOU N, HODGES J M, et al. Thermoelectrics: From history, a window to the future[J]. Materials ence and Engineering R Reports, 2018, DOI: 10.1016/j.mser.2018.09.001. |

| [6] |

QIN D D, CUI B, YIN L, et al. Tin acceptor doping enhanced thermoelectric performance of n-type Yb single-filled skutterudites via reduced electronicthermal conductivity[J]. ACS Appl Mater Interfaces, 2019, 11: 25133-25139. |

| [7] |

RO G L, G, GRYTSIV A, ANBALAGAN R, et al. Direct SPD processing to achieve high-zT skutterudites[J]. Acta Mater, 2018, 159: 352-363. |

| [8] |

RULLBRAVO M, MOURE A, FERNANDEZ J F, et al. Skutterudites as thermoelectric materials: Revisited[J]. Rsc Advances, 2015, 5(52): 41653-41667. |

| [9] |

SOOTSMAN J R, CHUNG D Y, KANATZIDIS M G. New and old concepts in thermoelectric materials[J]. Angew Chem Int Edit, 2009, 48(46): 8616-8639. |

| [10] |

ISLAM S M K N, LI M, AYDEMIR U, et al. Giant enhancement of the figure-of-merit over a broad temperature range in nano-boron incorporated Cu2Se[J]. Journal of Materials Chemistry A, 2018, 6(38): 18409-18416. |

| [11] |

POWELL A V. Recent developments in Earth-abundant copper-sulfide thermoelectric materials[J]. Journal of Applied Physics, 2019, DOI: 10.1063/1.5119345. |

| [12] |

ZHANG J W, WU Z W, XIANG B, et al. Ultralow lattice thermal conductivity in SnTe by incorporating with InSb[J]. ACS Applied Materials & Interfaces, 2020, DOI: 10.1021/acsami.0c03315. |

| [13] |

ZHOU Z F, CHAI Y W, IKUTA Y, et al. Reduced thermal conductivity of Mg2(Si, Sn) solid solutions by a gradient composition layered microstructure[J]. ACS Applied Materials & Interfaces, 2020, DOI: 10.1021/acsami.0c02549. |

| [14] |

HONG M, CHEN Z G, YANG L, et al. Achieving zT > 2 in p-Type AgSbTe2−xSex Alloys via exploring the extra light valence band and introducing dense stacking faults[J]. Advanced Energy Materials, 2018, 8(9): 1702333. |

| [15] |

OLVERA A A, MOROZ N A, SAHOO P, et al. Partial indium solubility induces chemical stability and colossal thermoelectric figure of merit in Cu2Se[J]. Energy & Environmental Science, 2017, 10(7): 1668-1676. |

| [16] |

SHUAI J, SUN Y, TAN X J, et al. Manipulating the Ge vacancies and Ge precipitates through Cr doping for realizing the high-performance GeTe thermoelectric material[J]. Small, 2020, DOI: 10.1002/smll.201906921. |

| [17] |

HONG M, WANG Y, FENG T L, et al. Strong phonon-phonon interactions securing extraordinary thermoelectric Ge1-xSbxTe with Zn-alloying-induced band alignment[J]. Journal of the American Chemical Society, 2019, 141(4): 1742-1748. |

| [18] |

ROWE D M. Thermoelectrics handbook[J]. Thermoelectrics Handbook Macro to Nano, 2005, DOI: 10.1201/9781420038903. |

| [19] |

HOLLOWAY J M, NORDSTROM D K, BOHLKE J K, et al. Ammonium in thermal waters of yellowstone national park: processes affecting speciation and isotope fractionation[J]. Geochimica Et Cosmochimica Acta, 2011, 75(16): 4611-4636. |

| [20] |

KAUR P, MADSEN G K H, BERA C. Thermoelectric figure of merit and thermal conductivity of type-I clathrate alloy nanowires[J]. Mrs Communications, 2019, 9(1): 70-374. |

| [21] |

QIN D D, WU H J, CAI S T, et al. Enhanced thermoelectric and mechanical properties in Yb0.3Co4Sb12 with In situ formed CoSi nanoprecipitates[J]. Advanced Energy Materials, 2019, 9(42), |

| [22] |

PASCHEN S, CARRILLO-CABRERA W, BENTIEN A, et al. Structural, transport, magnetic and thermal properties of Eu8Ga16Ge30[J]. Phys Rev B, 2001, 64(21): 214404. |

| [23] |

SINGH D J. Theoretical and computational approaches for identifying and optimizing novel thermoelectric materials[J]. Recent Trends Thermoelectr Mater Res, 2001, 70: 125-177. |

| [24] |

SALES B C, MANDRUS D, WILLIAMS R K. Filled skutterudite antimonides: A new class of thermoelectric materials[J]. Science, 1996, 272: 1325-1328. |

| [25] |

GHOSH S, VALIYAVEETTIL S M, SHANKAR G, et al. Enhanced thermoelectric properties of In-filled Co4Sb12 with InSb nanoinclusions[J]. Acs Applied Energy Materials, 2020, 3(1): 635-646. |

| [26] |

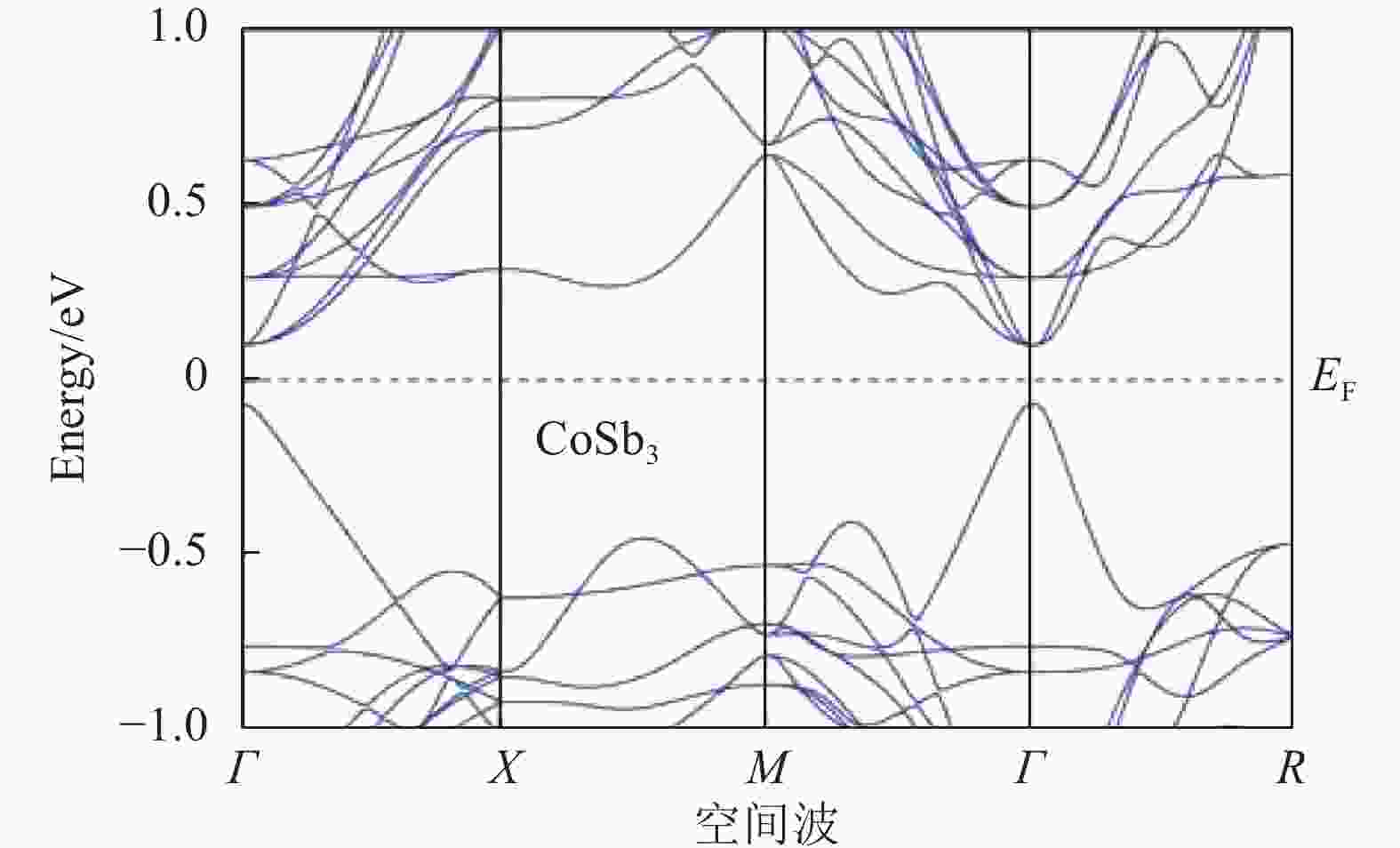

ANNO H, MATSUBARA K, CAILLAT T, et al. Valence-band structure of the skutterudite compounds CoAs3, CoSb3 and RhSb3 studied by x-ray photoelectron spectroscopy[J]. Phys Rev B, 2000, 62(16): DOI: http:\\dx.doi.org/10.1103/physRevB.62.10737. |

| [27] |

HERMANN R P, JIN R, SCHWEIKA W, et al. Einstein oscillators in thallium filled antimony skutterudites[J]. Physical Review Letters, 2003, 90(13): 135505. |

| [28] |

NOLAS G S, SLACK G A, MORELLI D T, et al. The effect of rare-earth filling on the lattice thermal conductivity of skutterudites[J]. Journal of Applied Physics, 1996, 79(8): 4002-4008. |

| [29] |

席丽丽, 杨炯, 史迅, 等. 填充方钴矿热电材料: 从单填到多填[J]. 中国科学: 物理学 力学 天文学, 2011, 41: 706-728. |

XI L L, YANG J, SHI X, et al. Filled skutterudites: From single to multiple filling[J]. Sci Sin Phys Mech Astron, 2011, 41: 706-728. |

| [30] |

CAILLAT T, BORSHCHEVSKY A, FLEURIAL J P. Properties of single crystalline semiconducting CoSb3[J]. Journal of Applied Physics, 1996, 80(8): 4442-4449. |

| [31] |

ALLENO E, ZEHANI E, GABORIT M, et al. Mesostructured thermoelectric Co1−yMySb3 (M = Ni, Pd) skutterudites[J]. Journal of Alloys and Compounds, 2017, 692: 676-686. |

| [32] |

MI J L, ZHAO X B, ZHU T J, et al. Thermoelectric properties of skutterudites FexNiyCo1−x−ySb3(x=y)[J]. Journal of Alloys & Compounds, 2008, 452(2): 225-229. |

| [33] |

KONG L J, JIA X P, SUN H R, et al. Influence of the high pressure and high temperature synthesis on thermoelectric properties of Ni-doped skutterudite[J]. Journal of Alloys and Compounds, 2017, 697: 257-261. |

| [34] |

WAN S, QIU P F, HUANG X Y, et al. Synthesis and thermoelectric properties of charge-compensated SyPdxCo4−xSb12 skutterudites[J]. Acs Applied Materials & Interfaces, 2018, 10(1): 625-634. |

| [35] |

ALLENO E, ZEHANI E, ROULEAU O. Metallurgical and thermoelectric properties in Co1−xPdxSb3 and Co1−xNixSb3 revisited[J]. Journal of Alloys & Compounds, 2013, 572(36): 43-48. |

| [36] |

LEI Y, GAO W S, ZHENG R, et al. Ultrafast synthesis of Te-Doped CoSb3 with excellent thermoelectric properties[J]. Acs Applied Energy Materials, 2019, 2(6): 4477-4485. |

| [37] |

ZHANG Q, LI X H, KANG Y L, et al. High pressure synthesis of Te-doped CoSb3 with enhanced thermoelectric performance[J]. Journal of Materials Science-Materials in Electronics, 2015, 26(1): 385-391. |

| [38] |

LIANG T, SU X L, YAN Y G, et al. Panoscopic approach for high-performance Te-Doped skutterudite[J]. NPG Asia Mater, 2017, 9(2), |

| [39] |

SHAHEEN N, SHEN X, JAVED M S, et al. High-temperature thermoelectric properties of Ge-substituted p-type Nd-filled skutterudites[J]. Journal of Electronic Materials, 2017, DOI: 10.1007/s11664-016-5079-z. |

| [40] |

MACKEY J, DYNYS F, HUDAK B M, et al. CoxNi4−xSb12−ySny skutterudites: Processing and thermoelectric properties[J]. Journal of Materials Science, 2016, 51(13): 6117-6132. |

| [41] |

FU L, JIANG Q, YANG J, et al. Enhancement of thermoelectric properties of Ce0.9Fe3.75Ni0.25Sb12 p-type skutterudite by tellurium addition[J]. Journal of Materials Chemistry A, 2016, DOI: 10.1039/C6TA06325J. |

| [42] |

FU L, YANG J, JIANG Q, et al. Thermoelectric performance enhancement of CeFe4Sb12 p-type skutterudite by disorder on the Sb rings induced by te doping and nanopores[J]. Journal of Electronic Materials, 2016, 45(3): 1240-1244. |

| [43] |

DIMITROV I K, MANLEY M E, SHAPIRO S M, et al. Einstein modes in the phonon density of states of the single-filled skutterudite Yb0.2Co4Sb12[J]. Phys Rev B, 2010, 1(8): 2821-2829. |

| [44] |

SU X, HAN L, YAN Y, et al. Microstructure and thermoelectric properties of CoSb2.75Ge0.25−xTex prepared by rapid solidification[J]. Acta Materialia, 2012, 60(8): 3536-3544. |

| [45] |

JIANG Y P, JIA X P, MA H G. The thermoelectric properties of CoSb3 compound doped with Te and Sn synthesized at different pressure[J]. Modern Physics Letters B, 2017, 31(28), |

| [46] |

SUN H, JIA X, DENG L, et al. Impacts of both high pressure and Te–Se double-substituted skutterudite on the thermoelectric properties prepared by HTHP[J]. Journal of Alloys & Compounds, 2014, 615: 1056-1059. |

| [47] |

DUAN B, ZHAI P, LIU L, et al. Effects of Se substitution on the thermoelectric performance of n-type Co4Sb11.3Te0.7−xSex skutterudites[J]. Materials Research Bulletin, 2012, 47(7): 1670-1673. |

| [48] |

BO D, ZHAI P, XU C, et al. Thermoelectric performance of tellurium and sulfur double-substituted skutterudite materials[J]. Journal of Materials Science, 2014, 49(13): 4445-4452. |

| [49] |

MALLIK R C, ANBALAGAN R, ROGL G, et al. Thermoelectric properties of Fe0.2Co3.8Sb12−xTex, skutterudites[J]. Acta Materialia, 2013, 61(18): 6698-6711. |

| [50] |

XU C, DUAN B, DING S, et al. Thermoelectric properties of skutterudites Co4−xNixSb11.9−yTeySe0.1[J]. Journal of Electronic Materials, 2014, 43(6): 2224-2228. |

| [51] |

BOUHAFS C, CHITROUB M, SCHERRER H. Synthesis and thermoelectric characterizations of Pd and Se-doped skutterudite compound[J]. Journal of Materials Science-Materials in Electronics, 2018, 29(2): 1264-1268. |

| [52] |

IOANNIDOU A A, RULL M, MARTIN-GONZALEZ M, et al. Microwave synthesis and characterization of the series Co1−xFexSb3 high temperature thermoelectric materials[J]. Journal of Electronic Materials, 2014, 43(7): 2637-2643. |

| [53] |

LIU Y, LI X, ZHANG Q, et al. High pressure synthesis of p-type Fe-substituted CoSb3 skutterudites[J]. Journal of Materials Science: Materials in Electronics, 2016, 27(6): 6433-6437. |

| [54] |

JEITSCHKOW, FOECKER A J, PASCHKE D, et al. Crystal structure and properties of some filled and unfilled skutterudites: GdFe4P12, SmFe4P12, NdFe4As12, Eu0.54Co4Sb12, Fe0.5Ni0.5P3, CoP3 and NiP3[J]. Zeitschrift Für Anorganische Und Allgemeine Chemie, 2015, 626(5): 1112-1120. |

| [55] |

KEPPENS V, MANDRUS D, SALES B C, et al. Localized vibrational modes in metallic solids[J]. Nature, 1998, 395(6705): 876-878. |

| [56] |

LI J,DUAN B, YANG H J, et al. Thermoelectric properties of electronegatively filled SyCo4−xNixSb12 skutterudites[J]. Journal of Materials Chemistry C, 2019, 90(26): 8079-8085. |

| [57] |

LI W, MINGO N. Ultralow lattice thermal conductivity of the fully filled skutterudite YbFe4Sb12 due to the flat avoided-crossing filler modes[J]. Phys Rev B, 2015, 91(14): 95-98. |

| [58] |

SHI X, BAI S, XI L, et al. Realization of high thermoelectric performance in n-type partially filled skutterudites[J]. Journal of Materials Research, 2011, 26: 1745-1754. |

| [59] |

CHEN L D. Recent advances in filled skutterudite systems[C]//International Conference on Thermoelectrics. [S.l.]: IEEE, 2002, DOI: 10.1109/ICT.2002.1190261. |

| [60] |

SHI X, KONG H, LI C P, et al. Low thermal conductivity and high thermoelectric figure of merit in n-type BaxYbyCo4Sb12 double-filled skutterudites[J]. Applied Physics Letters, 2008, 92(18): 407-253. |

| [61] |

YANG J, ZHANG W, BAI S Q, et al. Dual-frequency resonant phonon scattering in BaxRyCo4Sb12 (R=La, Ce, and Sr)[J]. Applied Physics Letters, 2007, 90(19), |

| [62] |

LU Q M, ZHANG J X, ZHANG X, et al. Effects of double filling of La and Ce on thermoelectric properties of CemLanFeCo3Sb12 compounds by spark plasma sintering[J]. Journal of Applied Physics, 2005, 98(10), |

| [63] |

TIAN Y F, SIRUSI A A, BALLIKAYA S, et al. Charge-carrier behavior in Ba-, Sr- and Yb-filled CoSb3: NMR and transport studies[J]. Physical Review B, 2019, |

| [64] |

QIU P, XUN S, QIU Y, et al. Enhancement of thermoelectric performance in slightly charge-compensated CeyCo4Sb12 skutterudites[J]. Applied Physics Letters, 2013, 103(6): 1745. |

| [65] |

KIM J, OHISHI Y, MUTA H, et al. Enhanced thermoelectric properties of Ga and Ce double-filled p-type skutterudites[J]. Materials Transactions, 2019, 60(6): 1078-1082. |

| [66] |

LI X H, KANG Y L, CHEN C, et al. Thermoelectric properties of high pressure synthesized lithium and calcium double-filled CoSb3[J]. AIP Advances, 2017, |

| [67] |

SALVADOR J R, YANG J, WANG H, et al. Double-filled skutterudites of the type YbxCayCo4Sb12: Synthesis and properties[J]. Journal of Applied Physics, 2010, DOI: 10.1063/1.3296186. |

| [68] |

BAI S Q, HUANG X Y, CHEN L D, et al. Thermoelectric properties of n-type SrxMyCo4Sb12(M=Yb, Ba) double-filled skutterudites[J]. Applied Physics A: Materials Science & Processing, 2010, 100(4): 1109-1114. |

| [69] |

ZHAO W, WEI P, ZHANG Q, et al. Enhanced thermoelectric performance in barium and indium double-filled skutterudite bulk materials via orbital hybridization induced by indium filler[J]. Journal of the American Chemical Society, 2009, 131(10): 3713-20. |

| [70] |

NOVIKOV S V, BURKOV A T, TANG X, et al. Thermoelectric properties of melt-spun and crystalline In0.2Ce0.1Co4Sb12.3 ribbons[J]. Materials Today-Proceedings, 2019, 8: 713-717. |

| [71] |

BASHIR M B A, SABRI M F M, SAID S M, et al. Enhancement of thermoelectric properties of Co4Sb12 skutterudite by Al and La double filling[J]. Journal of Solid State Chemistry, 2020: 284. |

| [72] |

GUO L, WANG G, PENG K, et al. Melt spinning synthesis of p-type skutterudites: Drastically speed up the process of high performance thermoelectrics[J]. Scripta Materialia, 2016, 116: 26-30. |

| [73] |

JEON B J, SHIN D K, KIM I H. Synthesis and thermoelectric properties of La1−zYbzFe4−xNixSb12, skutterudites[J]. Journal of Electronic Materials, 2016, 44(3): 1-7. |

| [74] |

SHIN D K, KIM I H, JANG K W, et al. Charge transport and thermoelectric properties of double-filled Nd1 –zYbzFe4 –xCoxSb12 skutterudites[J]. Journal of the Korean Physical Society, 2016, 68(7): 875-882. |

| [75] |

SONG K M, SHIN D K, JANG K W, et al. Synthesis and thermoelectric properties of Ce1−zPrzFe4−xCoxSb12, skutterudites[J]. Journal of Electronic Materials, 2016, DOI: 10.3938/jkps.67.1597. |

| [76] |

SONG K M, SHIN D K, KIM I H. Thermoelectric properties of p-Type La1−zPrzFe4−xCoxSb12, skutterudites[J]. Journal of Electronic Materials, 2016, 45(3): 1227-1233. |

| [77] |

JOO G S, SHIN D K, KIM I H. Synthesis and thermoelectric properties of p-type double-filled Ce1−zYbzFe4−xCoxSb12, skutterudites[J]. Journal of Electronic Materials, 2016, 45(3): 1251-1256. |

| [78] |

SHI X, YANG J J, SALVADOR J R, et al. Multiple-filled skutterudites: High thermoelectric figure of merit through separately optimizing electrical and thermal transports[J]. Journal of the American Chemical Society, 2012, 134(5): 2842-2842. |

| [79] |

ROGL G, GRYTSIV A, ROGL P, et al. n-Type skutterudites (R, Ba, Yb)yCo4Sb12 (R = Sr, La, Mm, DD, SrMm, SrDD) approaching ZT approximate to 2.0[J]. Acta Materialia, 2014, 63: 30-43. |

| [80] |

KUMAR M, RANI S J, SINGH Y, et al. Tuning the thermoelectric material's parameter: A comprehensive review[J]. Journal of Nanoscience and Nanotechnology, 2020, 20(6): 3636-3646. |

| [81] |

SANTOS R, YAMINI S A, DOU S X, et al. Recent progress in magnesium-based thermoelectric materials[J]. Journal of Materials Chemistry A, 2018, 6(8): 3328-3341. |

| [82] |

KHAN A U, KOBAYASHI K, TANG D M, et al. Nano-micro-porous skutterudites with 100% enhancement in ZT for high performance thermoelectricity[J]. Nano Energy, 2017, 31: 152-159. |

| [83] |

ZHENG ZH, WEI M, LI F, et al. Improvement of power factor of CoSb3 thermoelectric thin films via microstructure optimization[J]. Coatings, 2017, 7(11): 205. |

| [84] |

WU Z H, MU E, CHE Z X, et al. Nanoporous (00l)-oriented Bi2Te3 nanoplate film for improved thermoelectric performance[J]. Journal of Alloys and Compounds, 2020, 828: 154239. |

| [85] |

LIANG G X, ZHENG Z H, LI F, et al. Nano structure Ti-doped skutterudite CoSb3 thin films through layer inter-diffusion for enhanced thermoelectric properties[J]. Journal of the European Ceramic Society, 2019, 39(5): 4842-4849. |

| [86] |

ZHENG Z H, LI F, LI F, et al. Thermoelectric properties of co-sputtered CoSb3 thin films as a function of stoichiometry[J]. Thin Solid Films, 2017, 632: 88-92. |

| [87] |

ZHENG Z H, LI F, LUO J T, et al. Thermoelectric properties and micro-structure characteristics of nano-sized CoSb3 thin films prefabricating by co-sputtering[J]. Journal of Alloys and Compounds, 2018, 732: 958-962. |

| [88] |

DANIEL M V, HAMMERSCHMIDT L, SCHMIDT C, et al. Structural and thermoelectric properties of FeSb3 skutterudite thin films[J]. Physical Review B, 2015, 91(8), |

| [89] |

DANIEL M V, LINDORF M, ALBRECHT M. Thermoelectric properties of skutterudite CoSb3 thin films[J]. Journal of Applied Physics, 2016, 120(12): 1665. |

| [90] |

LONSKY M, HEINZ S, DANIEL M V, et al. Electronic transport in thermoelectric YbzCo4Sb12 skutterudite thin films studied by resistance noise spectroscopy[J]. Journal of Applied Physics, 2016, 120(14): 433-448. |

ISSN

ISSN

DownLoad:

DownLoad: