-

Hydrogenated amorphous silicon (a-Si: H) films have a wide range of practical applications, particularly in mirco-electromechanical system (MEMS), photovoltaic and photodetection. And plasma enhanced chemical vapor deposition (PECVD) is generally used as the deposition method of a-Si: H films for enabling large area deposition and high-quality film. Previous studies have demonstrated the fact of surface morphology of the PECVD-deposited a-Si film related to the substrate material[1-6]. Ref. [1] reported that smooth a-Si film without hillocks is formed on the 100 nm oxide/Si substrate while a rough surface with many hillocks is formed on the crystalline Si substrate. Ref. [2] discussed the influence of the PECVD parameters on the surface roughness of a-Si: H film, and the optimized deposition conditions to suppress the formation of gas bubbles in thick a-Si: H film deposited on silicon substrate. Ref. [3] considered some strategies to mitigate the formation of those micro-bubbles, and found a dramatic improvement in surface roughness quality in their experiment. In addition, some works have demonstrated that bubble defects are also formed on a-Si film after the process of annealing, which is resulted from the accumulation of hydrogen molecules on the film-substrate interface as hydrogen diffused from the film[4-6]. Previous works on the surface morphology of the PECVD-deposited a-Si film mainly focused on the bubble defects’ formation mechanism and the corresponding suppression methods, but ignored the potential applications of this kind of self-formed surface microstructure.

In this paper, we prepared a-Si: H film on crystalline silicon substrate, with nonuniformly distributed bubbles observed on the surface, which is consistent with the results in previous literatures. The latest advance in micro- and nano-fabrication lies in self-assembly or self-organization techniques[7-9], but to the best of our knowledge, few reports on this kind of novel self-formed technique. This technique has advantages in easier process and lower cost, indicates a high feasibility and a good prospect in the field of nanophotonics and MEMS.

-

The a-Si: H film was deposited directly on crystalline silicon substrate by PECVD with RF power of 80 W, chamber pressure of 370 mTorr, temperature of 320 ℃ and SiH4 gas flow rate of 100 sccm. Then, without breaking vacuum, the SiNx film was also prepared by PECVD with RF power of 140 W, chamber pressure of 480 mTorr, temperature of 320 ℃ and NH3/SiH4 gas flow rate of 225/50 sccm. The surface morphology and bubble defect microstructure are characterized by using optical microscope and scanning electron microscope (SEM).

-

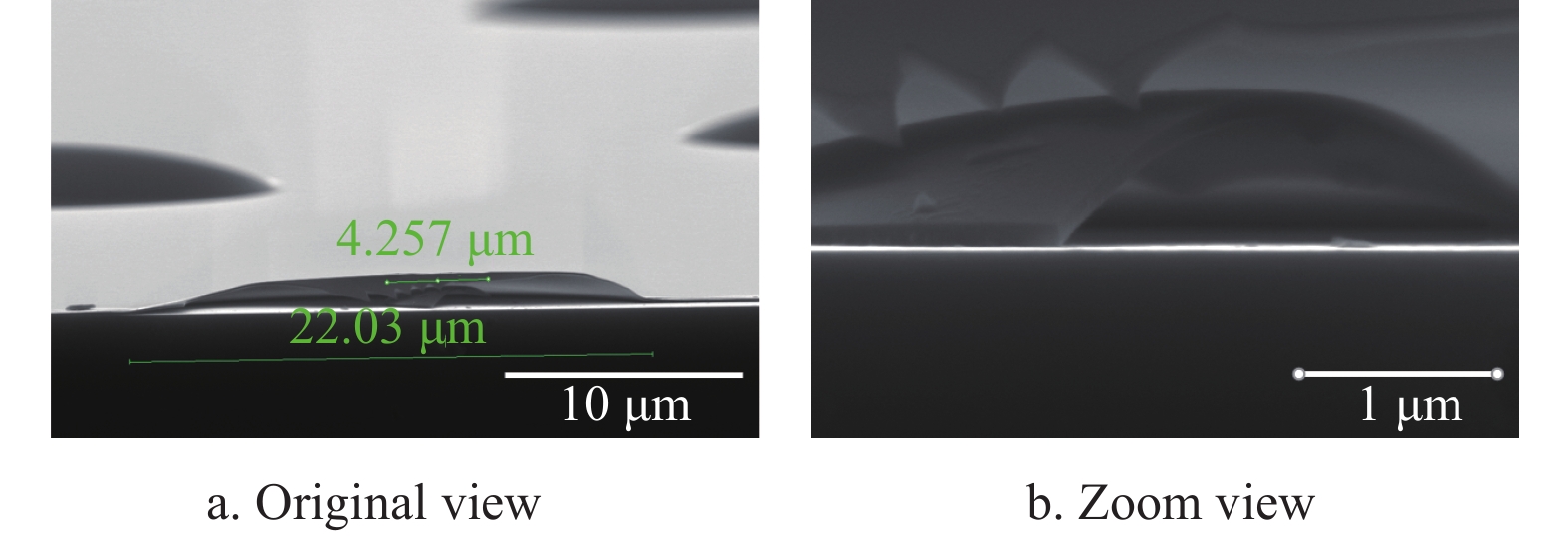

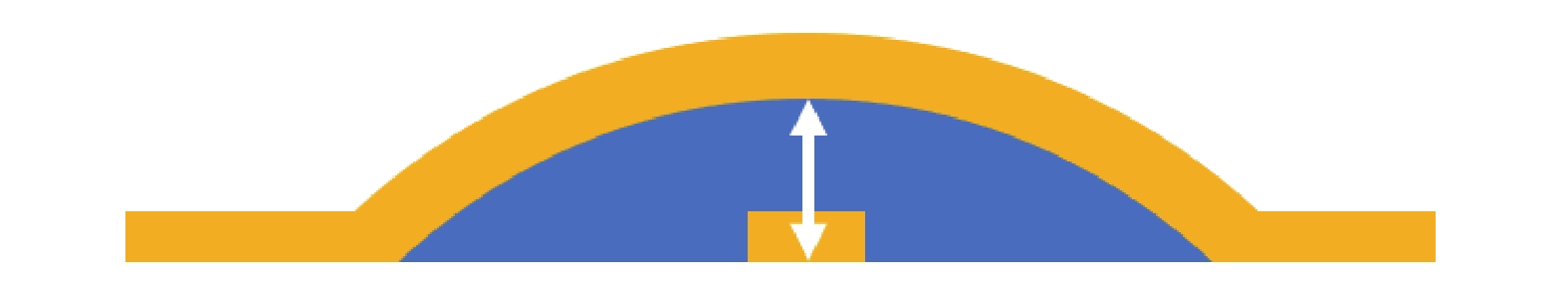

Nonuniformly distributed micro-bubbles are observed on the surface of the deposited a-Si on crystalline silicon substrate. Fig. 1 shows representative micro-bubbles obtained by optical microscope, and the characteristics size of micro-bubbles decreases with the deposition time, and the density increases with the deposition time. The formation of such bubble defects in a-Si: H films has been previously reported and has been attributed to trapped hydrogen gas unable to escape[3-6]. The perfect dome morphology is as a result of film stress. The film stress increases with the deposition time, which leads to a smaller size of micro-bubbles, which is consistent with the results obtained in the experiment.

Figure 1. Optical micrograph of single layer a-Si film with nonuniform bubbles formation at varied deposition times

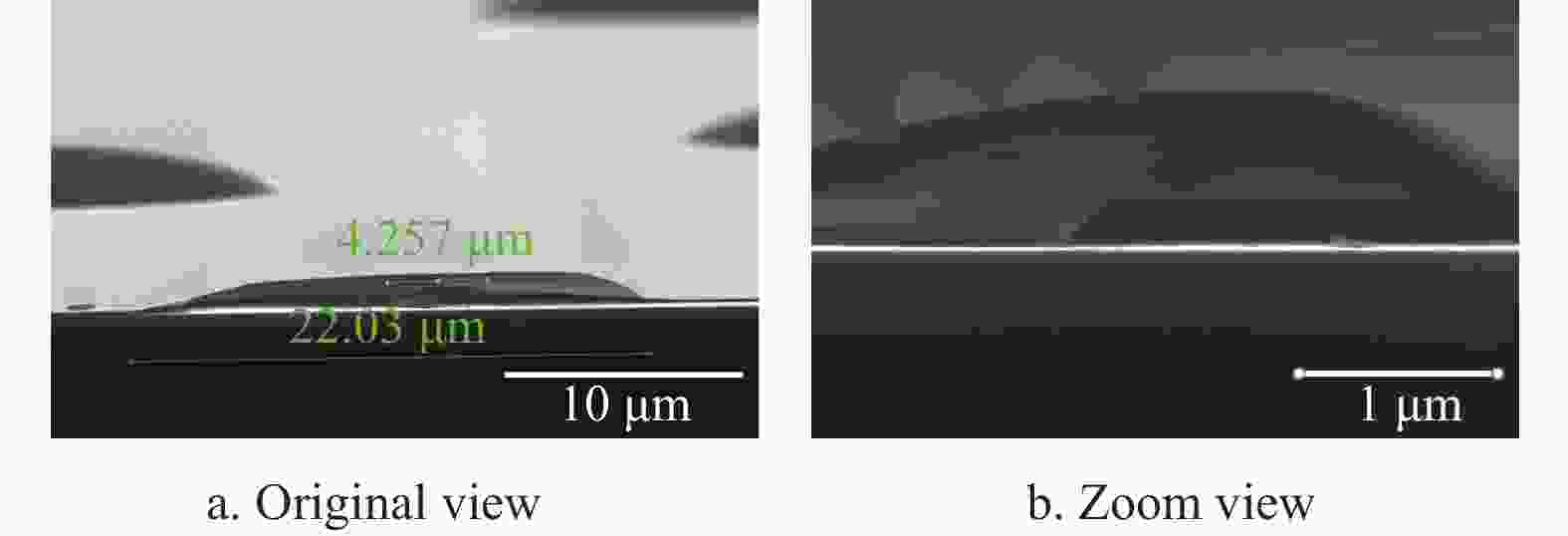

As shown in Fig. 2, the cross-section SEM image of as-prepared a-Si film demonstrated an interesting microstructure characteristic with a double-dome morphology, as shown in Fig. 2a. Fig. 2b depicted that the inner dome presented an appearance of discontinuous film, while the outer dome presented an appearance of continuous film. The double-dome morphology is not universal, most of the micro-bubbles have single-dome morphology, as shown in Fig. 3~Fig. 5. The deposition of a-Si films is more complicated than simple homoepitaxy. Growth mechanisms are related to varying sticking coefficients, extraction reactions, precursor diffusion, hydrogen diffusion and evolution, and subsurface cross linking of silicon[10]. Here the smaller bubble formed as inner dome is attributed to low cluster mobility at the nucleation sites. This double-dome morphology effect might be suppressed by optimized fabrication process.

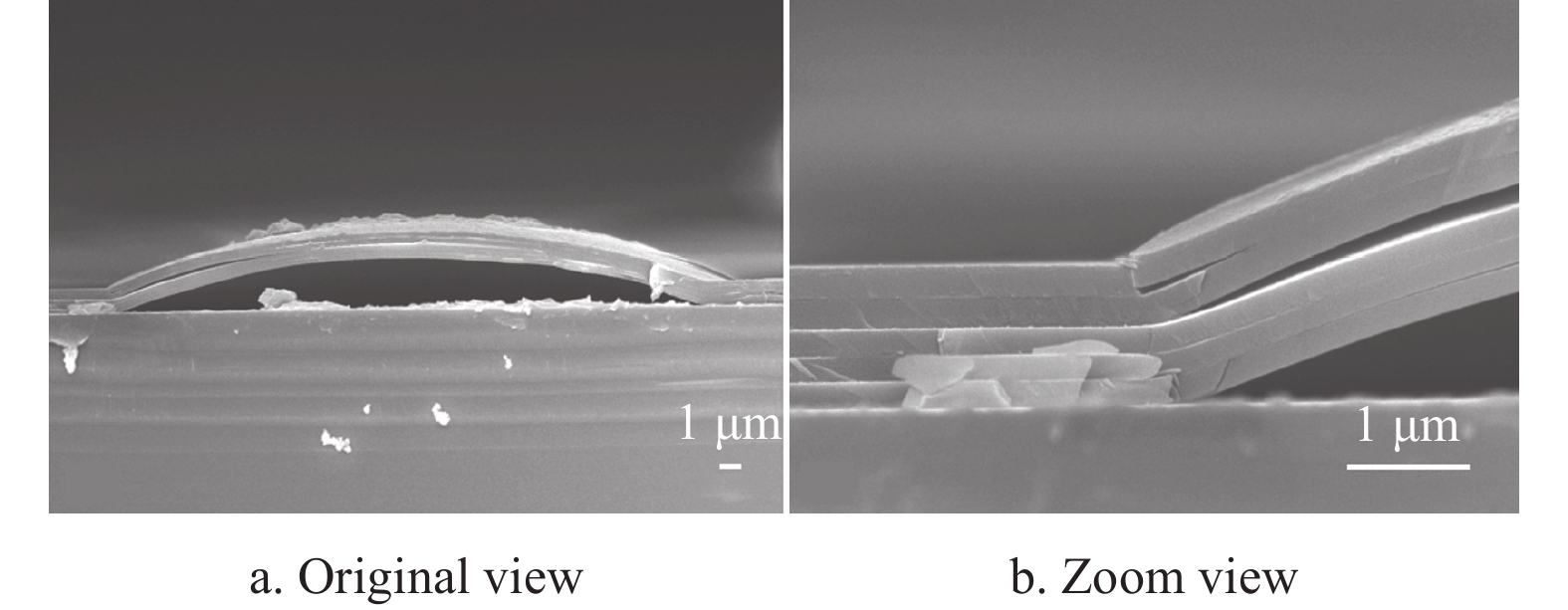

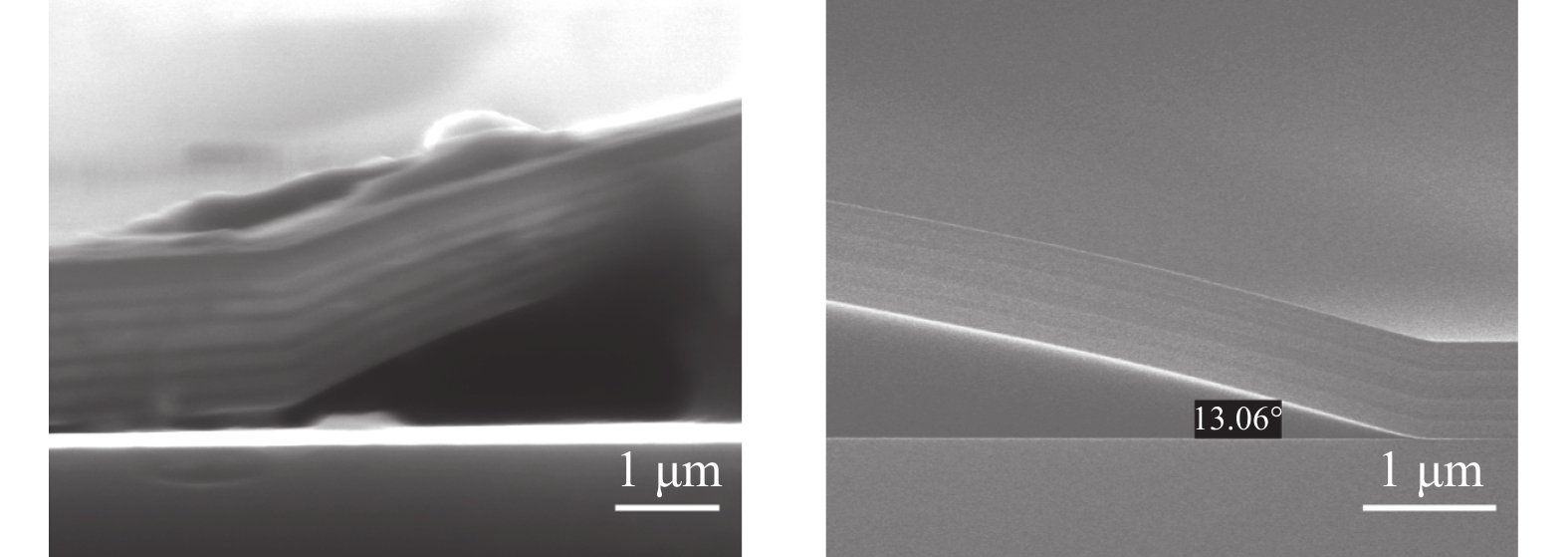

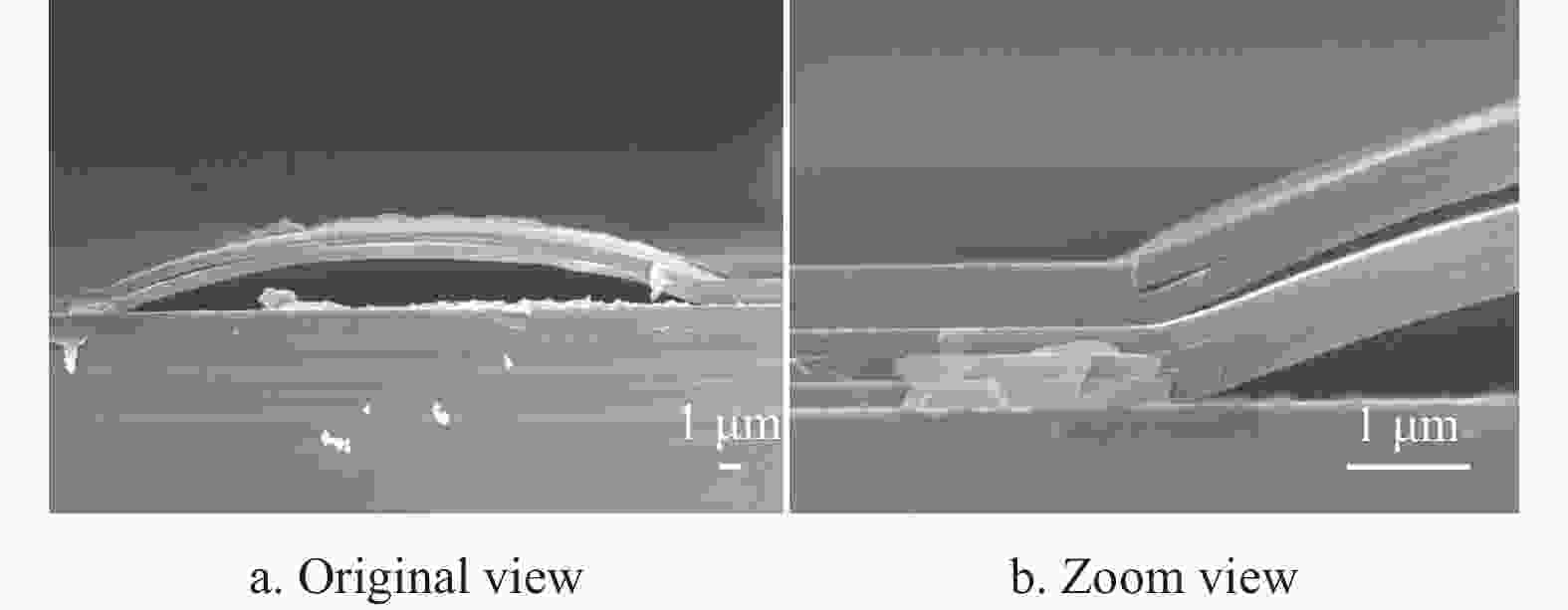

Fig. 3 shows the micrography of SiNx/a-Si alternative layer with 2-pairs prepared on the as-prepared a-Si film with self-formed surface microstructures. The top and bottom layers are both a-Si films. As shown in Fig. 3b, the subsequent SiNx/a-Si film deposition on as-prepared a-Si film shows perfect conformal characteristics. However, the delamination occurred between the third layer and the fourth layer (from bottom to top), which is attributed to the film stress and film adhesion. Further optimization of fabrication process can suppress the delaminated phenomenon.

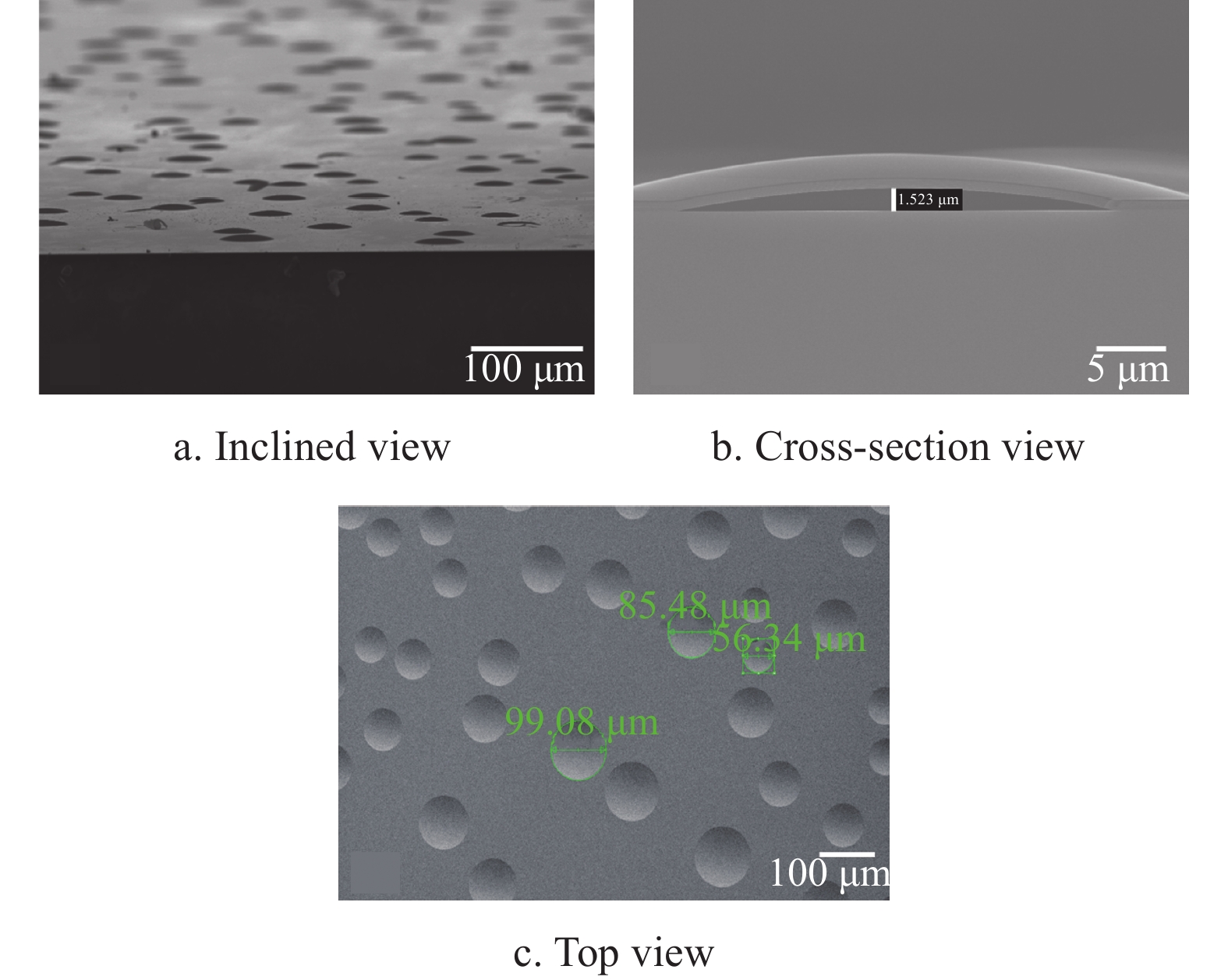

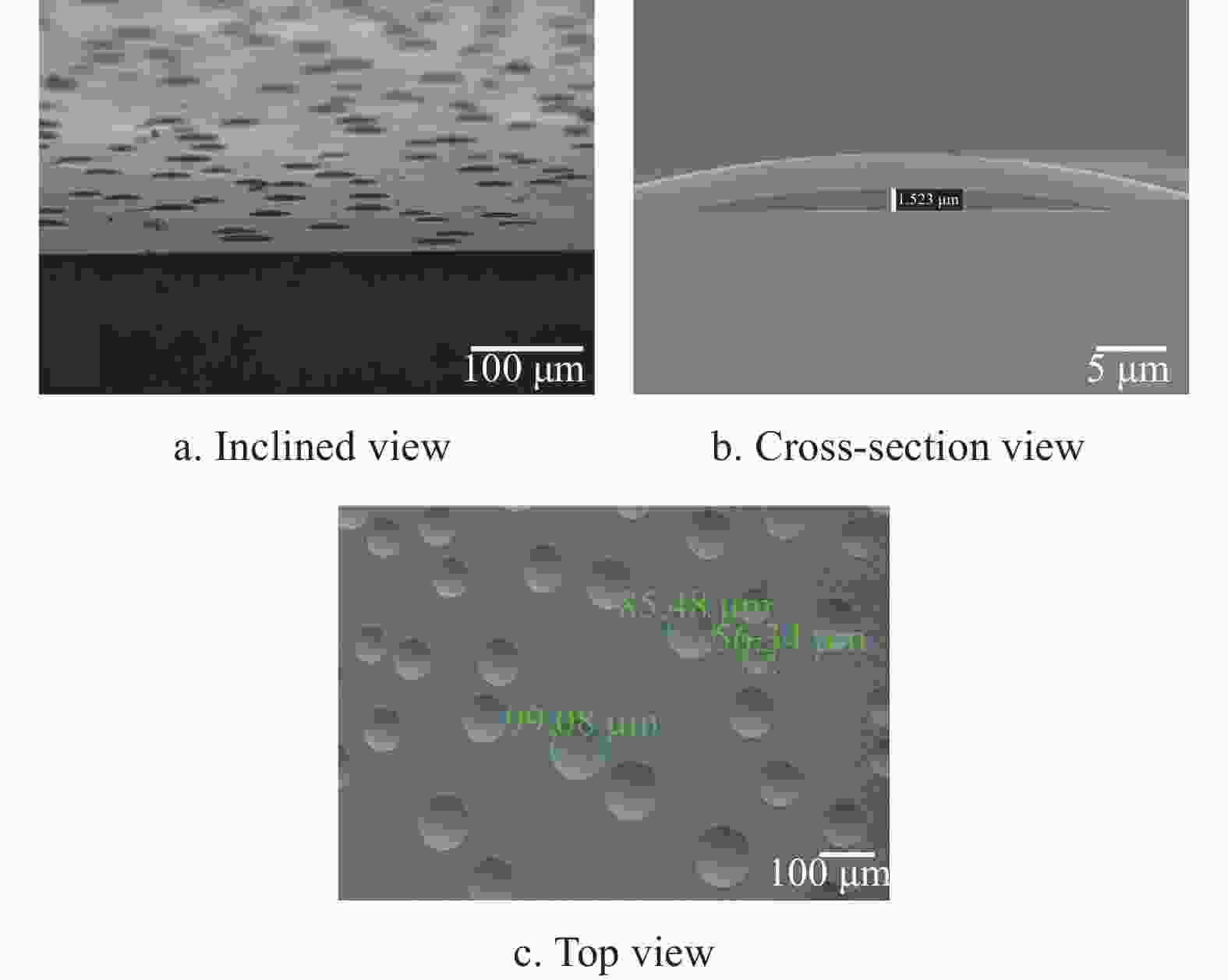

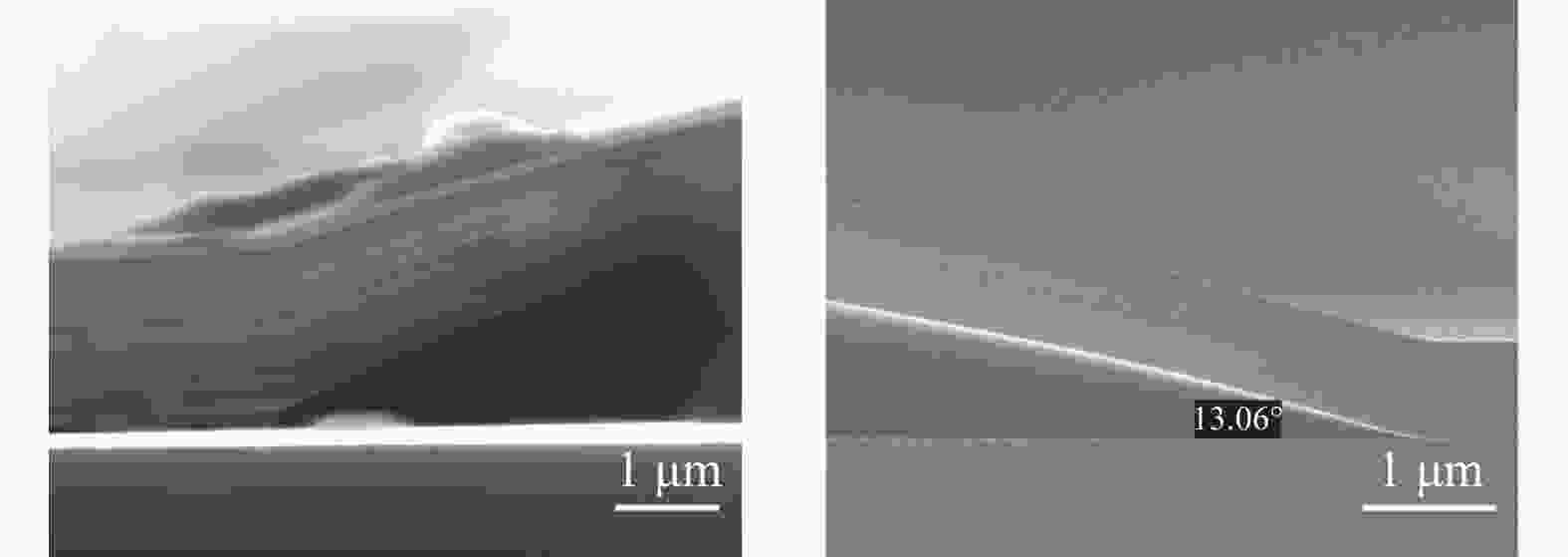

To verify the strong mechanical properties of our self-formed silicon microstructures, we further prepared SiNx/a-Si alternative layer with 4-pairs on as-prepared a-Si film. The morphology characteristics are shown in Fig. 4 and Fig. 5, we can see that the dome-shaped multi-shell microstructures show perfect conformal characters with no distinct structural collapse, which demonstrated a certain mechanical strength. The total thickness of SiNx/a-Si alternative layer is approximately 0.74 μm with an improved film adhesion and uniformity. Such a dome-shaped multi-shell microstructure may have lots of potential applications in the field of nanophotonics and MEMS.

-

We can conclude three unique characteristics of the dome-shaped multi-shell microstructure: 1) a self-formed microstructure with a dome-shape; 2) controllable size of structure; 3) good mechanical properties. Based on these three characteristics, we propose and discuss three potential applications here.

-

Considering the characteristics of self-formed curved surface, the surface plasmons in graphene can be trapped and guided in its curved landscapes. Ref. [11] demonstrated that graphene placed on top of curved substrates offers a novel approach for trapping and guiding surface plasmons. Monolayer graphene with a spatially varying curvature exhibits an effective trapping potential for graphene plasmons near curved areas. This concept can be utilized in other 2D materials for their plasmons excited. Furthermore, some studies have demonstrated the multiple optical resonance properties involved in dome-shaped micro/nanostructures, including localized surface plasmon resonance (LSPR) modes, waveguide modes, whispering gallery modes (WGMs). A similar work reported by Ref. [12] has demonstrated the feasibility of using dome-shaped resonators based on the whispering gallery modes as an untethered sensing element for remote temperature measurement.

-

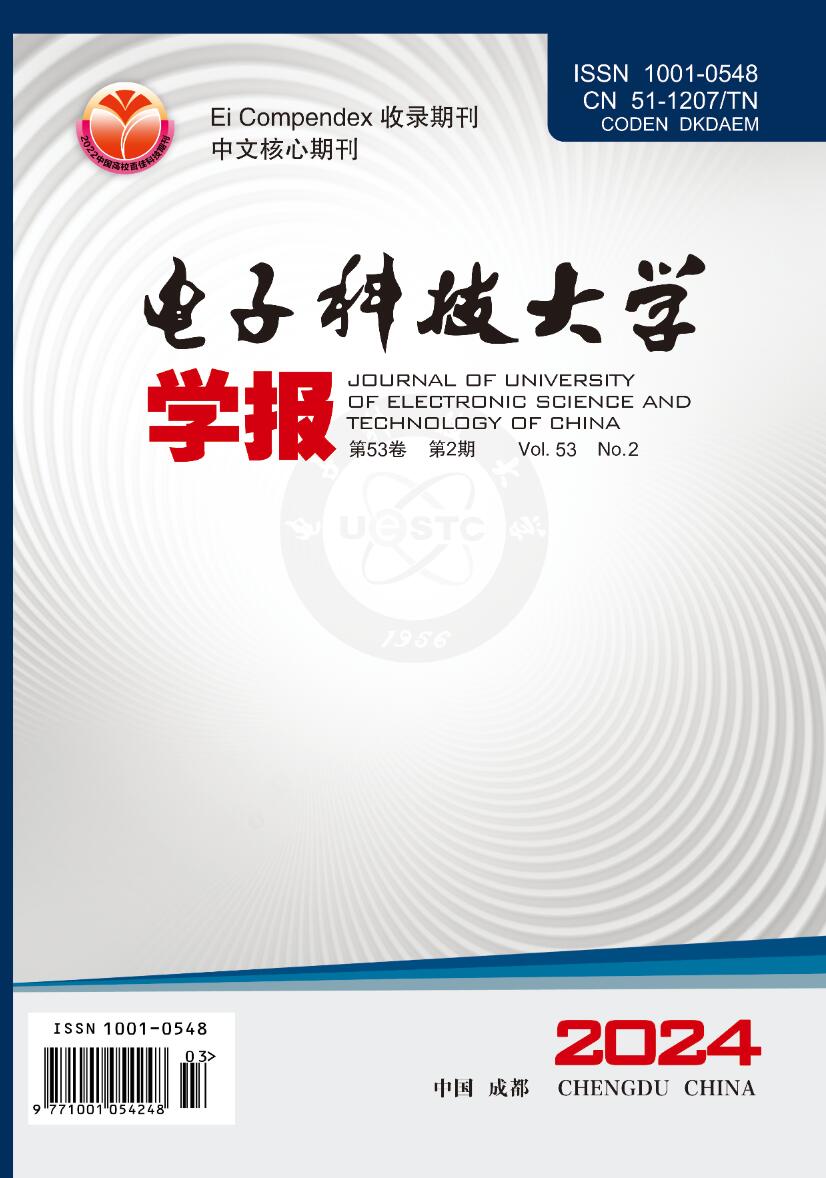

We considered the perfect self-formed dome-shape microstructures and their good mechanical properties, which provide new possibilities for the fabrication of three-dimensional microstructure as well as some novel sensors. Some arched or domed MEMS microstructure can be fabricated, as shown in Fig. 6. By depositing or transferring two materials with different thermal expansion coefficients on the as-prepared a-Si film to form a bi-material cantilever beam, the underneath a-Si film can be removed by wet-etching, and the top films can be retained as the basic components of a mechanical actuated sensor, which can be designed for thermal sensing, stress sensing. Similar works have been reported by Ref. [13-14]. They present a plasmonic metamaterial that supports the thermomechanically coupled optical and mechanical resonances for controlling optical damping of mechanical resonance. However, the systems driven by metamaterial-based configuration are much more complicated, and a multi-step lithography process is required. Our self-formed dome-shape microstructure provide a easier fabrication of cantilever structures.

-

The good mechanical properties of the dome-shaped microstructures provide the possibility for micro-lens design and fabrication. Single micro-lens and micro-lens arrays have been developed in the past for applications in photolithography, imaging, and light communications. And the common fabrication methods include soft lithographic techniques or femtosecond laser direct writing[15-16], which is costed and even complicated. This work provided a novel method for the optimized fabrication of the micro-lens. It should be noted that the random distribution of the bubbles in our self-formed fabrication method makes it difficult to fabricate the array patterns. Accordingly, it requires further studies on the bubbles’ distribution mechanism and control means for enabling the potential application in micro-lens array.

-

We demonstrated that the nonuniformly distributed bubble defects are formed during the process of a-Si: H films deposited on crystalline silicon substrate. And dome-shaped multi-shell microstructures are formed by SiNx/a-Si alternative layers deposited on the as-prepared a-Si: H films with good adhesion between film layers and no distinct structural collapse, whose size can be controlled by fabrication process. These self-formed dome-shaped microstructures have potential applications in nanophotonics and optical sensing fields. This work also provides some processing ideas for complex 3D microstructures and MEMS sensors design.

A Self-Formed Silicon Surface Microstructure: Surface Characterization and Potential Applications

doi: 10.12178/1001-0548.2022206

- Received Date: 2022-07-05

- Rev Recd Date: 2022-09-29

- Available Online: 2024-04-01

- Publish Date: 2024-03-30

-

Key words:

- MEMS /

- amorphous silicon films /

- blister defect /

- self-formed /

- silicon micro/nanostructures

Abstract: The morphology of hydrogenated amorphous silicon (a-Si: H) films grown by plasma enhanced chemical vapor deposition (PECVD) is studied. Nonuniformly distributed bubble defects are formed during the process of a-Si: H films deposited on crystalline silicon substrate. The SiNx/a-Si alternative layers are deposited on the as-prepared a-Si: H film, a perfect dome-shaped multi-shell microstructure was formed at the site of the blister defect, and no distinct structural collapse was observed. Three unique characters of the self-formed dome-shape microstructure are concluded, and the potential applications of the proposed self-formed dome-shape microstructure in nanophotonics and MEMS are also pointed out.

| Citation: | LI Jiacheng, LIU Shuang, WU Shenglan, LIU Yong, ZHONG Zhiyong. A Self-Formed Silicon Surface Microstructure: Surface Characterization and Potential Applications[J]. Journal of University of Electronic Science and Technology of China, 2024, 53(2): 180-184. doi: 10.12178/1001-0548.2022206 |

ISSN

ISSN

DownLoad:

DownLoad: