-

半导体工业的高速发展在迅速提高电子芯片晶体管密度与运算能力的同时,也导致电子芯片释热强度的大幅增加,这要求芯片冷却装置具有更强的散热能力,才能保证芯片的正常工作。目前,冷却系统换热能力不足[1-4]已经成为集成电路技术进一步发展的主要瓶颈之一。另一方面,电子系统往往空间狭小,要求芯片冷却装置结构紧凑、布置灵活。微通道热沉(MHS)主要由大量微通道组成,增加了换热面积,从而使其具有很强的换热能力,但散热均匀性差且流动阻力大也是其固有缺点[5-6]。

分流式微通道热沉(MMHS)在微通道上增加了分流道结构。文献[7]首次提出MMHS结构,MMHS将微通道内工质由单一进出口的流动改变为多进口和多出口的流动过程,在提高换热能力和换热均匀性的同时,还减少了工质的流动阻力[7-9]。文献[8]通过计算分析发现MMHS微通道入口处换热能力最强,微通道底面受冷却工质冲击处及微通道出口也有很强的强化传热效应。文献[9]认为MMHS的强化换热能力与微通道内较大的速度梯度及产生的流体漩涡有关,同时也指出分流通道向微通道内的分流过程存在流量分配不均现象。已有一些研究者对MMHS与MHS的换热性能做了对比,文献[10-11]分别通过实验对比发现,MMHS总体热阻比MHS低约30%~35%。

近年来关于MMHS的研究多以结构优化及改进为主[12-14],这些措施使MMHS具备了更好的散热能力与散热均匀性。文献[12]通过结构优化引导更多冷却流体分配到MMHS中热负荷较高的区域,同时该区域的微通道尺度更小、数量更多,从而可获得更大换热面积。文献[13]将MMHS的分流道分割成多个相对独立的单元,使冷却流体多次流入、流出这分流通道,提高了冷却流体的换热效率,进一步起到强化换热的作用。文献[14]针对一种具有自相似结构的分流式微通道热沉(self-similarity microchannel heat sink, SSHS),提出了结构改进方案,通过采用渐缩式分流通道结构,解决了SSHS内流量分配和换热不均的问题。

鉴于MMHS在换热方面的优越性和当前研究的不足,本文通过分析MMHS一个单元内的换热过程,分析其传热特点以及MHS之间的差异,为MMHS的设计和开发提供参考。

HTML

-

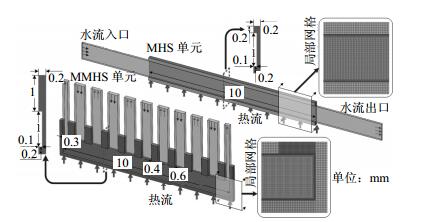

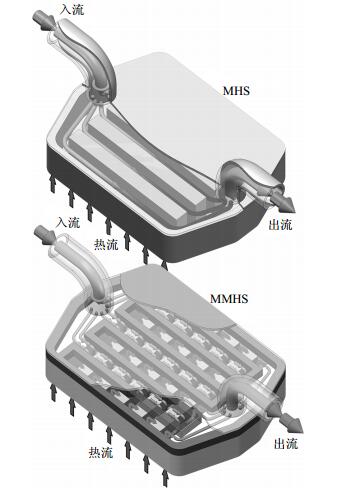

图 1为MHS和MMHS的结构示意图,为了对比MHS与MMHS换热过程的差异,分别从2个整体结构中各截取了一个完整的肋通道单元,对模拟计算的结果进行对比分析,单元模型及对应尺寸如图 2所示。MMHS的单元模型还包含分流道。为保证进入MHS微通道及MMHS分流道中的流体充分发展,同时消除进出口段效应,单元模型进出口分别加长约5倍进出口水力直径。

-

数值模拟采用ANSYS16.0中FLUENT模块。由于流动参数范围内微通道内的雷诺数均小于1 000,计算采用层流模型。冷却工质为水,其粘度由式(1)计算为:

式中,μ为粘度,单位为kg·m−1·s−1;T为水温,单位为K。MMHS与MHS的固体材料为硅。计算中做如下假设:1)流体不可压缩;2)不考虑重力影响;3)固体物性为常物性。

-

流体入口设为质量流入口边界条件,入流温度为308.15 K。对于MHS与MMHS,均计算5组流量,分别为0.37 kg/h、0.74 kg/h、1.12 kg/h、1.49 kg/h和1.86 kg/h。MMHS各分流通道入口流量之和与MHS对应工况入口流量相同。流体出口设为自由出流边界条件。单元模型两侧面设为对称边界条件。加热面上加入150 W/cm2的恒定热流,其余按默认固壁面处理。

-

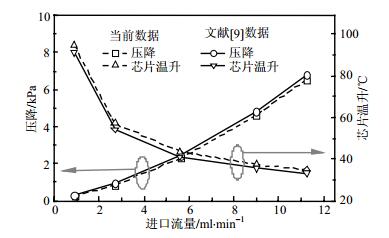

本文对微通道中靠近壁面的水体区域进行了网格加密,计算域网格划分如图 2所示。MHS及MMHS单元模型网格无关性验证表明:当MHS和MMHS网格数量分别达到75 w和120 w之后,继续增加网格数量,两者的进出口压降变化不大,在之后的模拟计算中,针对MHS和MMHS分别采用上述网格数量计算。为了进一步验证本文采用的数值计算方法的准确性,采用与文献[11]相同的尺寸结构模型,利用此方法进行了模拟计算,并与其计算结果进行了对比。对比结果如图 3所示,两者在不同流量下模拟得到的流动阻力压降和加热表面温升均很接近,本文计算方法的准确性和可靠性得以验证。另外,本文数值模拟方法与文献[14]中关于SSHS的研究采用的方法相近。同时,前述工作通过比较文献[15]的模拟结果以及实验测试结果,也验证了数值方法的准确性和可靠性。

1.1. 计算几何模型

1.2. 计算模型及假设条件

1.3. 边界条件及计算工况

1.4. 计算模型验证及网格无关性验证

-

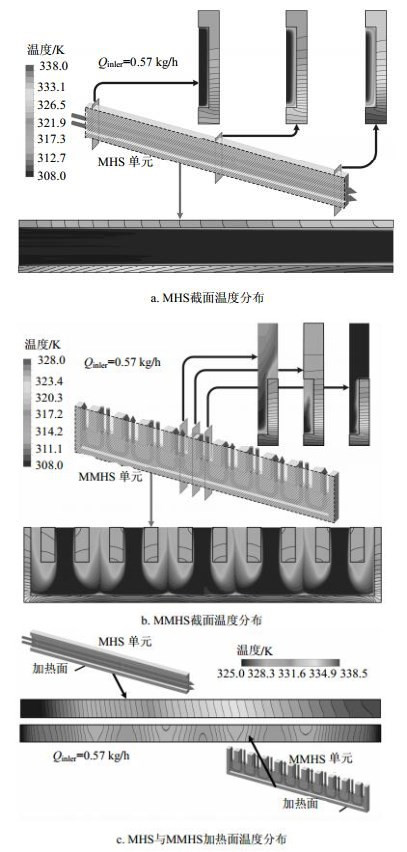

图 4为进口流量为0.57 kg/h时MHS与MMHS换热单元上中下游3个位置横截面及微通道加热面的温度分布情况。图 4中Qinlet为进口流量,对于MMHS,Qinlet为各入口总流量。从图 4a可以看出,MHS单元通道内工质沿流动方向不断被加热,换热主要发生于微通道内壁面附近;随着水温逐渐升高,换热强度逐渐下降,引起MHS固体导热部分温度逐渐升高。从图 4b可以看出,MMHS换热单元固体温度分布均匀性相比MHS有显著提高,加热面最高温度降低了10 K以上。图 4c进一步给出了两者在加热通道底部外壁面的温度分布,MHS单元温度由324 K变换至最高温度339 K,高低温差15 K;MMHS加热面最高温度仅为328 K,高低温差只有4 K。

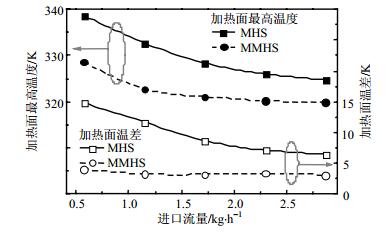

图 5进一步给出了流量在0.57~2.87 kg/h范围内时,MHS与MMHS的加热底面最高温度与高低温差变化情况。相同流量下,两者最低温度几乎相同,但MMHS的加热面最高温度比MHS低5 K以上。虽然随着流量的加大,MMHS强化换热的显著性有所降低,但依然将加热面温差降低了50%以上,说明MMHS的几何结构在改善传热过程方面起到了决定性作用。

-

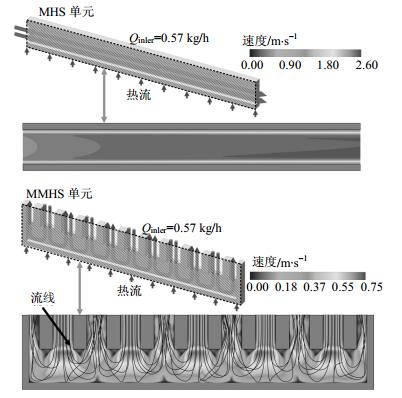

图 6给出了入口流量为0.57 kg/h时MHS与MMHS换热单元内中心截面的速度云图,可以清晰地展示出MMHS换热单元的射流过程。对于MHS而言,通道工质的流动方向与加热面平行,下游较厚的速度边界层不利于换热过程的强化。而对于MMHS,由于分流通道的存在,工质基本以垂直于加热面方向流动,形成了一定的射流过程,这势必会强化换热过程。一个微通道上方共有5个进口和5个出口,因此,相当于存在5个射流过程,同时将整个通道分成了5个部分,工质都以相同的入口温度进入微通道,从而可以大大提高换热的均匀性。

综合上述分析,MMHS的强化换热过程和换热均匀性提高的原因可以概括为两个方面:1)通过分流通道,将MHS工质单一进出口流动过程变为多个并行的进出口流动过程,相当于将一个微肋通道分割成若干个部分;2)工质在由分流通道向微通道流动过程中,形成了较强的射流过程,使换热过程得到强化。

根据数值计算结果还能进一步得到局部换热系数,其计算公式为:

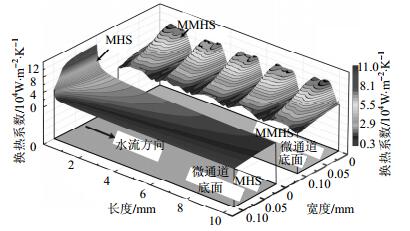

式中,hl为局部换热系数,单位为W·m-2·K-1;ql为当地热流,单位为W·m-2;Tw为当地壁面温度;Tf为当地流体温度,温度单位为K。图 7给出了入口流量为0.57 kg/h时,MHS与MMHS换热单元局部换热系数。MHS换热单元入口位置,由于入口段效应,换热能力最强,沿着流动方向,其换热能力迅速降低,局部换热系数下降幅度超过50%。对比MHS,MMHS换热微通道换热热系数整体分布均匀,局部传热系数最大,达到7.9×104 W·m-2·K-1;出流口对应位置附近换热系数最小,仅为1.8×103 W·m-2·K-1。

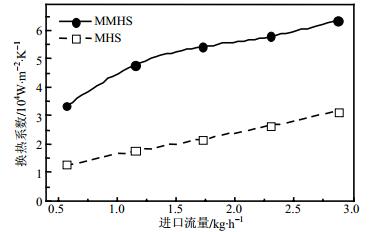

图 8给出了入口流量对MMHS与MHS平均换热系数的影响,当进口流量在0.57~2.87 kg/h范围内时,MMHS平均换热系数显著高于MHS,不同流量下均提高1倍以上。入流流量为1.15 kg/h时两者相差最大,MMHS平均换热系数比MHS高约173%。

2.1. 换热性能对比

2.2. MMHS强化换热机理分析

-

本文利用数值计算方法对比了MHS和MMHS传热特性的差异,给出了MMHS综合传热性能更好的原因,并得到以下结论:1) MMHS分流通道改变了原MHS微肋通道中冷却工质的流动过程,形成了多进口—多出口的通道结构。2)特殊的通道结构客观上造成了MMHS换热单元内一定的射流过程,起到了强化传热作用,在换热能力得到提高的同时,换热均匀性也得到提高。3)入口流量在0.57~2.87 kg/h范围内变化时,MMHS平均换热系数比MHS提高一倍以上,散热均匀性比MHS提高了52 %以上。

ISSN

ISSN

DownLoad:

DownLoad: